helical end mills feeds and speeds

High Helix Carbide End Mill At Rs 3000 Unit Solid Carbide End Mills Id 20478637012 Series 6774 Inch Rf100 Speed 4 Fl Extra Length End Mill Guhring 4 6 Flute High Feed End Mills Epic Tool. 1-888-868-5988 Technical Support Email.

Series 6773 Inch Rf100 Speed 4 Fl Std Length End Mill Guhring

The data is from tests performed by Celeritive Technologies Inc independent research facilities and existing customers.

. Simply search for your tool number and then click on Speeds Feeds in the resources section. PCD blanks feature high hardness high abrasive resistance high thermal conductivity and strong toughness. INDEXABLE INSERTS Company Profile Ordering Sales Support Contact Us SDS Safty Data Sheet.

6 flute speeds and feeds. View Speeds Feeds. SURFACE FEET PER MINUTES.

730 Corporate Woods PKWY Vernon Hills IL 60061 Phone. SFM FPT For Material 2. Machining Advisor Pro paired with Helical End Mills is the Holy Grail of End Mill Performance.

If you run your tool with too slow of a feed rate you run the risk of recutting chips and accelerating tool wear. Method B will expand the entry hole by. All cutting tools can shatter and break during use.

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill. Part of what makes Helical tools worthwhile is the. Tapered end mill usage can be tricky if the proper settings are not adhered to.

Machining Advisor Pro MAP generates specialized machining parameters by pairing the unique geometries of your Helical Solutions end mill with your exact tool path material and machine setup. HSMAdvisor by default suggests plunging Speed and Feed according to these guidelines. Feeding it too little or too much.

Find RPM at intersection of SFM Diameter. New Helical Machining Advisor Pro. No hard fast rule there but.

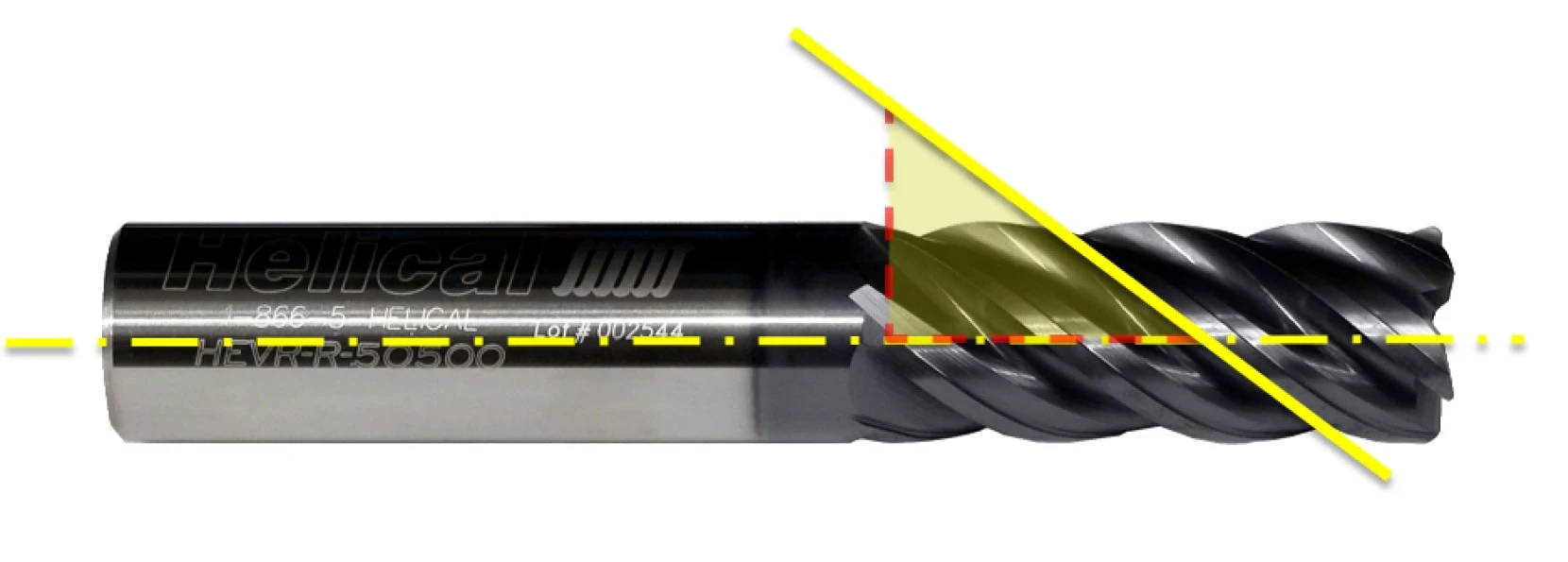

Determine the spindle speed RPM and feed rate IPM for a milling operation as well as the cut time for a given cut length. This is lesson 7. Variable Helix End Mills for Aluminum Alloys - Chipbreaker Roughers - Square The unique geometry of this solid carbide 3 flute Harvey Tool features a variable pitch design and chipbreaker geometry for reduced chatter and harmonics increased MRR and improved chip management while machining aluminum.

Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Our Viper DVH series end mills are for both roughing and finishing. Viper DVH Speeds Feeds.

The use life of a PCD End Mills can be up to 50X over carbide end mills. New Helical Machining Advisor Pro. Quick Navigation CNC Machining Top.

Aph Z-axis depth for one helical revolution circular 0 in. In addition to our Speeds Feeds Library you can also find specific running parameters directly on our product page and tool details page for every tool. Ingersoll supplies almost all my carbide insert tooling and I asked him about the Ingersoll carbide end mills.

Cm Number of circularhelical tool path revolutions. Helical PCD End Mills. Basically what it boiled down to was stick with Helical.

Helical speeds and feeds. Matters more as material machinability decreases. - The maximum feed for roughing is the high rate - The starting feed for the best finish is the low rate - The starting feed for roughing should be taken from the middle of the feed range Formulas.

MAP is our go-to solution for High Efficiency Milling and has exponentially decreased our run times as well as increased our tooling life. Convert linear feed to tool center feed to determine the feedrate. Feeds - IPT inchestooth and MMPT mmtooth Material.

SMM SFM X 3048. Since not every company has the RPM or need for high Metal Removal Rates MRR. PCD End Mill is a superior cutting tools capable of side cutting and center cutting with high feeds and speeds.

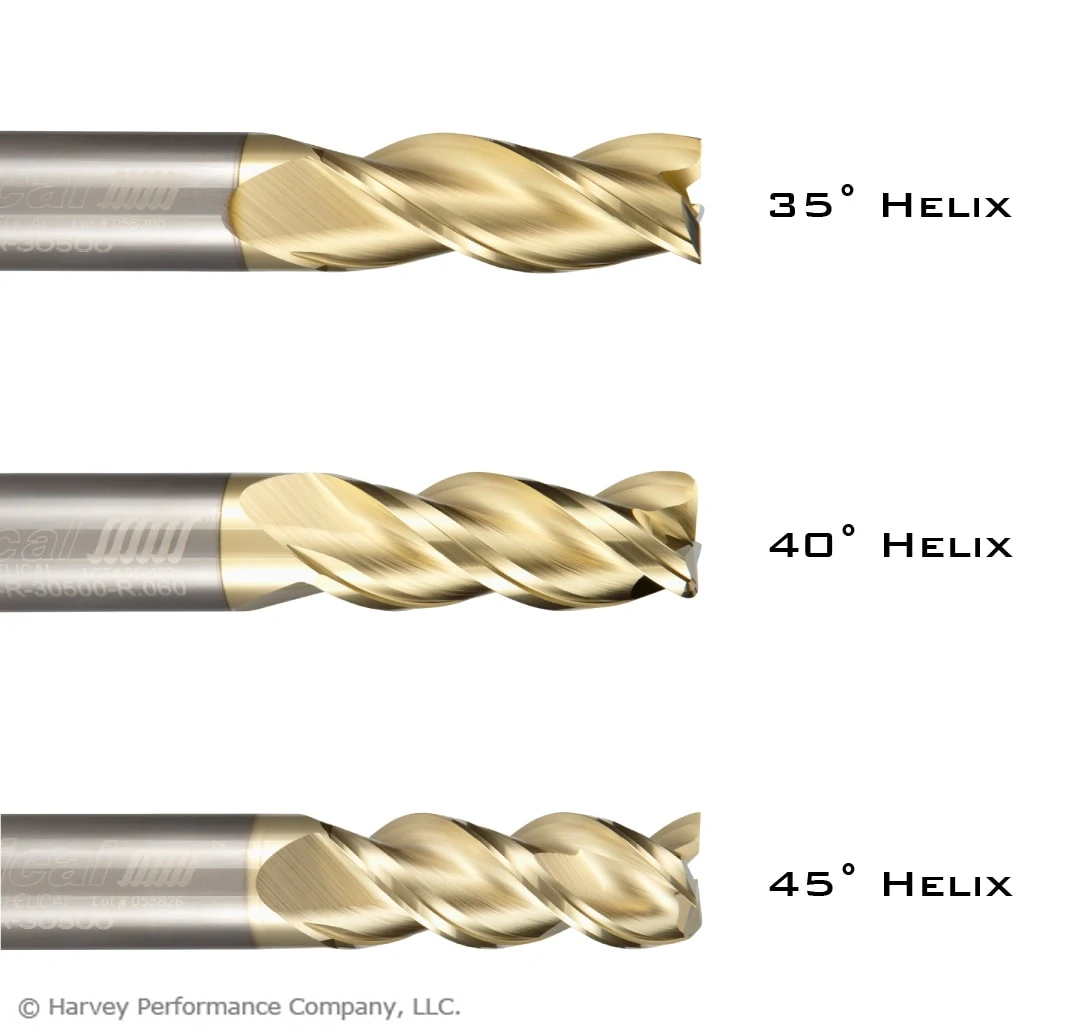

45 Degree Variable Helix Primarily for high-speed machining of aluminum plastics and other non-ferrous materials including brass and bronze alloys. Calculate Feed IPM FPT x Number of Flutes X RPM. Speeds and feeds speeds and feeds for key cutters material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15.

Milling Speed and Feed Calculator. The entry hole can be either a one-step or a two-step process depending on the number of flutes on the end mill. Using current input - Data results are for External Helical Interpolation.

MMPT Millimeter per tooth from the speed and feed charts Speed Surface feet per minute SFM or meters per min MMin. Helicals fully stocked offering of High Feed End Mills is designed for outstanding performance and maximum feed rates in aluminum and non-ferrous materials. To access speeds and feeds information for your Helical Solutions end mills we recommend using our Machining Advisor Pro application.

Getting the best performance from VoluMill toolpaths requires using more aggressive machining parameters than you may be used to. Helical makes the best endmills considering price and what they do for you. The data sheets below provide some examples of parameters used for milling various materials.

Manufacturing Engineer Waynesburg PA. Posted on January 31 2018 Leave a comment. Using Machining Advisor Pro is a no brainer its a standard.

Hanita used to be my favorite but Helical displaced them a few years back. High helix and variable helix cutters can leave a better finish. Variable helix end mills reduce chatter and vibration.

End Mill Speeds And Feeds - TiN Coated Carbide. When calculating spindle speed I recommend using 70 of normal slotting cutting speed for this material and the feedrate should be divided by the number the End Mills flutes. Mild - 1018 2-3 Carbon 420 0006016mm 0011028mm 0017043mm 002051mm.

Maximum depth per rev depends on the material toolhole diameter ratio tool and other factors. Its reduced neck geometry provides maximum strength in long reach and deep pocketing applications while its end profile provides optimal tool engagement and reduced cutting forces. IPT Inch per tooth from the speed and feed charts.

Ideally the depth of your plunge should not exceed one diameter of the end mill. 1070 1681 RPM 2292 Recommended RPM range is 1070 - 2292 RPM At the speed of 1681 RPM the recommended feed rate is 504 - 2017 IPM Interpreting Results. 1-847-634-3755 1-866-941-8665 Technical Support.

Helical Solutions Speeds Feeds. Calculations use the desired tool diameter. Government regulations require that safety glasses be worn during use.

Had my Ingersoll rep out here one day Ingersoll supplies almost all my carbide insert tooling and I asked him about the Ingersoll carbide end mills.

Cnc Router Bits Down Cut End Mills 1 4 Dia 3 Flute Low Helix Downcut Spiral End Mill Cnc Router Bit 1 4 Shank Yonico 36314 Sc

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool

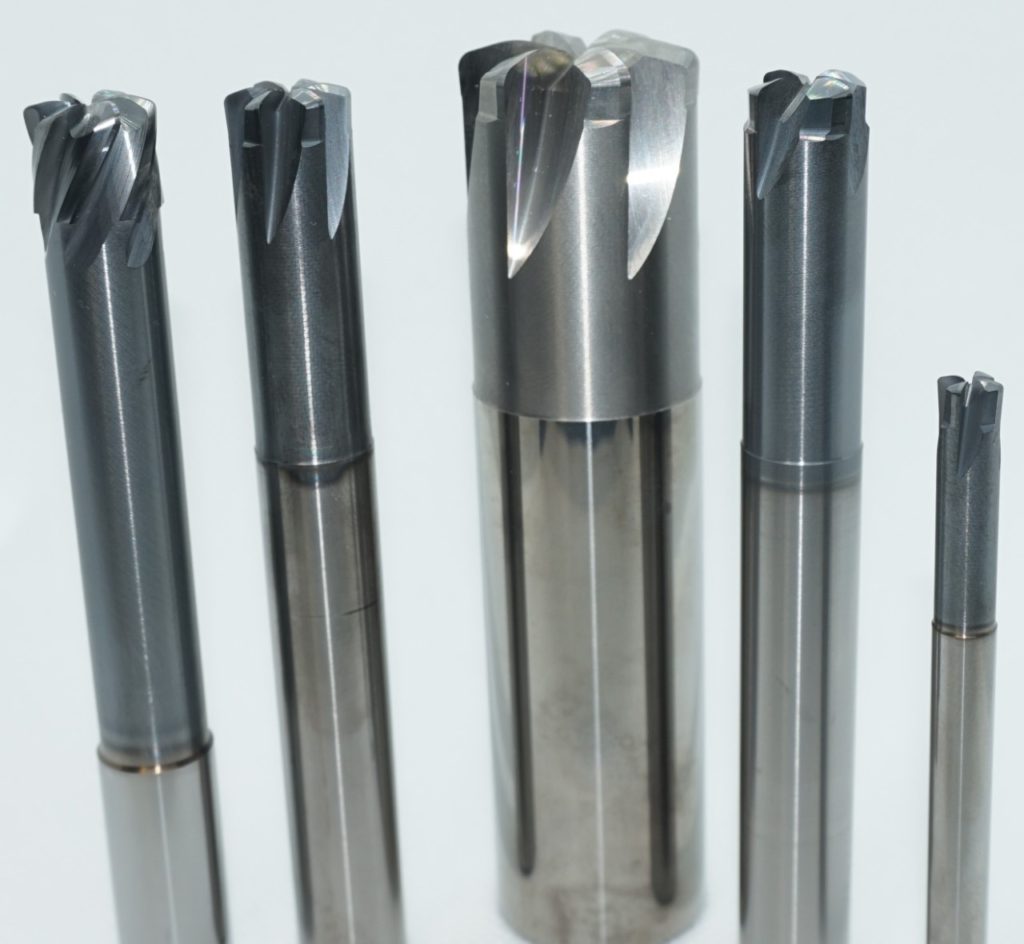

Global Cutting Tools End Mills Cutting Tools Metalworking Extreme3

Conical Tapered End Mills Cutting Tools Metalworking Helical Angle

End Mills Carbide Tools Online

Technology Spotlight High Speed Trochoidal Tools

3 Flute Square Aluminum End Mill Falcon Cutting Tools Inc

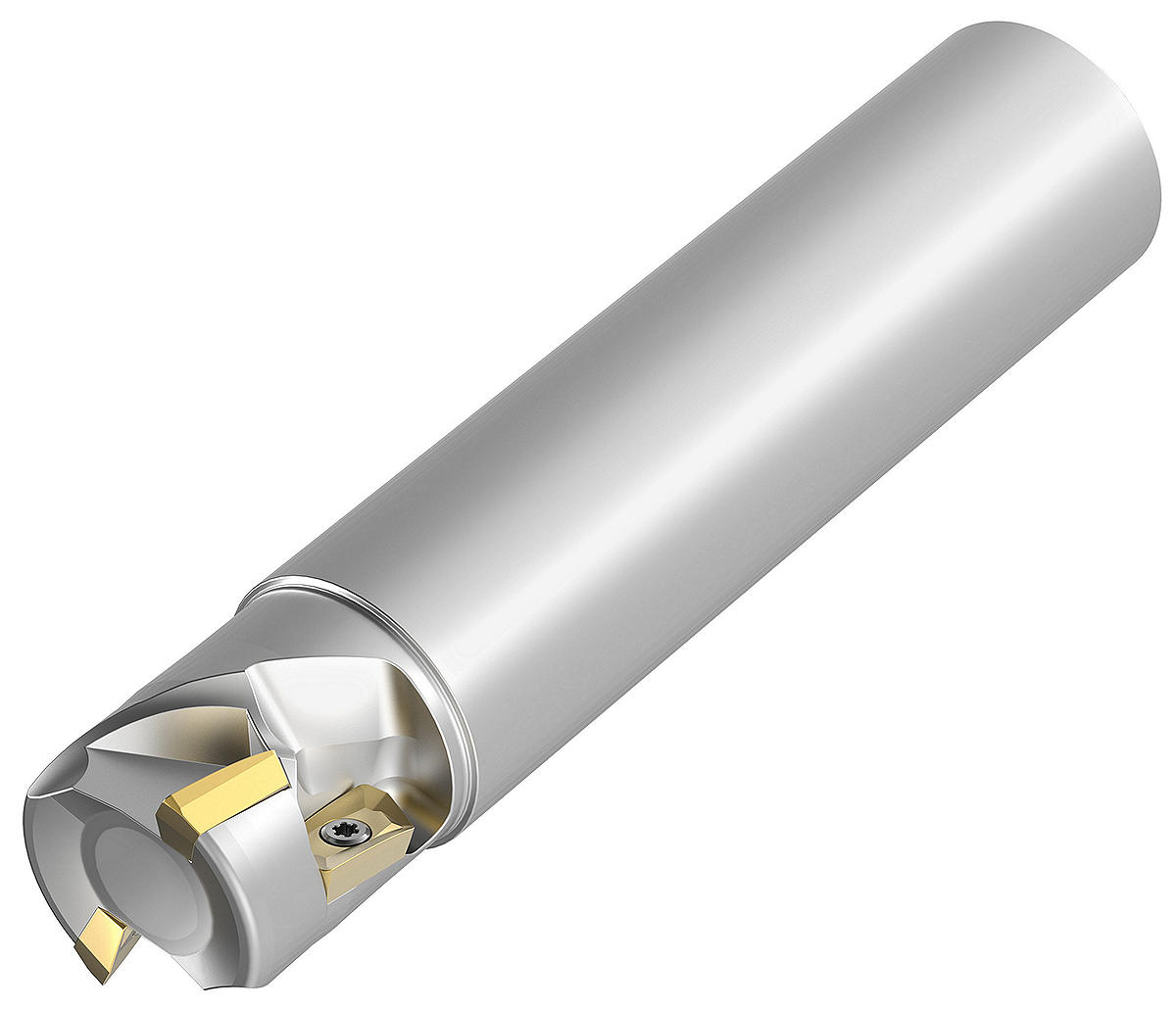

Mill 1 10 Helical Indexable Helical End Mills

End Mill An Overview Sciencedirect Topics

Cutting Tools Good Vibrations Blog Resources

Global Cutting Tools End Mills Cutting Tools Metalworking Vortex5

End Mills Milling Cutters High Speed Cobalt

4 6 Flute High Feed End Mills Epic Tool

Helix Diameter Archives Harvey Performance Company

Specification Variable Helix End Mill

Titanium Machining Cost Savings With Helical Solutions In The Loupe

Necked Tooling Archives Harvey Performance Company

Basic End Mills Technical Information Msc Industrial Supply Co

1575 4mm 3 Flute Carbide Ball End Mill Se 38 Deg Helix 551 Loc Maritool